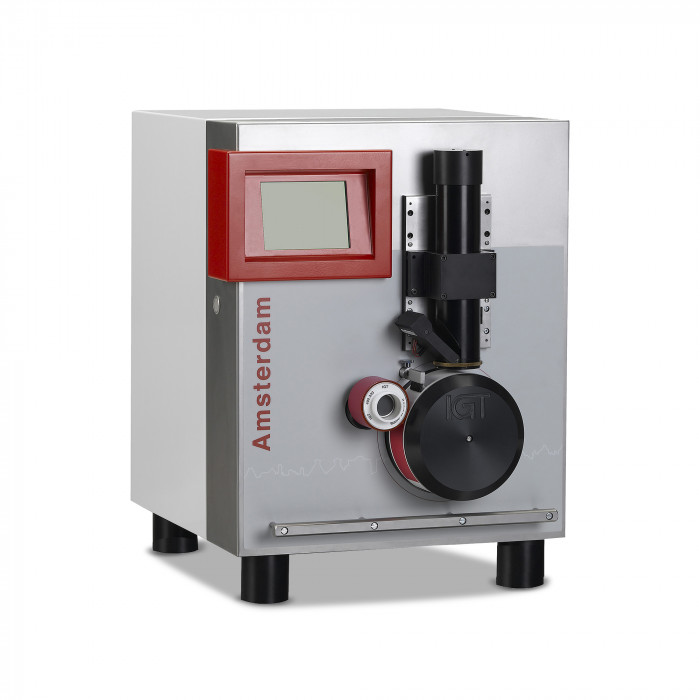

Amsterdam 1

Article number: 720.000.000

Multi-purpose printability tester with single print shaft.

New range of Printability testers with integrated, camera based, analysis systems. The range consits of devices with one to 6 printing shaft for maximum flexibility of test methods. The long range of test methods can be extended with user defined methods. With that it is capable to perform all tests of a Global Standard Tester P plus the tests of a Global Standard Tester 3.

Additionally it is prepared to do on-line analysis of mottling with a camera based analysis system.

•1 to 6 printing shafts, each can be equipped with a drive for printing in register if needed

•Very small interval times, down to 0,2 s

•Large number of test methods

•Very easy in operation

•In-line analysis of several test methods

•Export of scanned images

Single printing shaft, constant speed, accellerating speed, interval on multi-revolution prints, camera for image recording, optional analysis of heliotest, mottle, print penetration, IGT roughness, doctoring station for gravure printing, and hygro-expansivity, user programmable, recording of test data and settings, export of data on USB stick.

| Weight: | 110kg |

| Dimensions(L x W x H): | 59cm x 50cm x 64cm |

| Model: | 720.000.000 |

| Main application: | Pick testing Heliotest gravure printing Hydroexpansivity Density Colour and transparency Print penetration Mottle test Set-off test Toner adhesion |

| Conformance with standards/W-leaflet: | ISO 3783-2006, ISO 2834, ISO 2836, ISO 2846, NEN 1836, NEN 1839, EN 12283, ASTM D7680, |

| Water bath and temperature: | — |

| Speed range and modes: | Constant: 0.1 – 4.0 m/s in steps of 0.1 m/s Accelerating endspeed: 0.1 – 4.0 m/s in steps of 0.1 m/s |

| Forces: | 100 – 1000 N- step 1 N |

| Substrate requirements: | Flexible substrates |

| Interval time and number: | 1 – 600 s in steps of 1 s |

| Printing shafts type and options: | 1 print shaft |

| Shaft positioning: | Automatically, programmable |

| Lifting system: | Automatically |

| Print length and width: | 5-50 mm wide, 10-500 mm length (sector dependent), programmable, depends on printing form and test method |

| Printing discs: | Aluminium rubber blanket rubber Heliotest Gravure discs for specific test |

| Sector positioning: | Automatically, programmable |

| Sector type and options: | 180° sector with clamps, 360° sector without clamps with dfferent coverages |

| Doctoring system: | Standard at print shaft 1 |

| Dispensing system: | — |

| Pre-programmed tests: | Pick Heliotest Gravure Print penetration IGT Roughness Density Colour and transparency Hydroexpansivity toner adhesion custom made tests on request |

| Analysis options: | Heliotest, Mottle, Print penetration, IGT Roughnes, Hydroexpansivity |

| Interfaces: | USB portal |

| Software updates: | Via USB |

| Data export options: | Recording and export of images, settings and analysis results via USB |

| Additional items: | 466.000.000 High Speed Inking Unit 4 408.000.200 IGT ink Pipette 0.01 ml resolution 408.000.400 IGT ink Pipette 0.001 ml resolution 441.000 Pick Start Viewer PSV 441.000.040 Delamination/Blistering viewer |

| Accessories: | Heliotest set hygroexpansivity set gravure set pick set loose nd weakly bound particles set different printing discs for several applications westvaco inking set intaglio inking set |

| Inks or liquids: | Pick test oils, pick inks, penetration liquid, roughness liquid, setting ink, mottling ink, density ink, |

| Inking speeds: | — |

| Inking programs: | — |

| Top rollers: | — |

| Maintenance: | Yearly. The annual maintenance and calibration of the tester can be carried out by IGT Testing Systems or companies authorized by IGT Testing Systems. Information can be obtained from your supplier or the local agent. |

| Compatible instruments: | AIC2-5 Global Standard Tester 2 AIC2-5T2000 Amsterdam 2 Amsterdam 5 Amsterdam 6 |

| Measurement range: | — |

| Light source/ power/angle: | — |

| Volume: | — |

| Shelf life: | — |

| Use life: | — |

| Description of property: | — |

| Cleaning: | — |

| Power Supply Requirements: | 115 V 50/60 Hz or 230 V 50/60 Hz |

| Guarantee: | Standard one year |

| Space requirements: | 0.7 m2 |

| Standard delivery time: | 10-12 weeks |