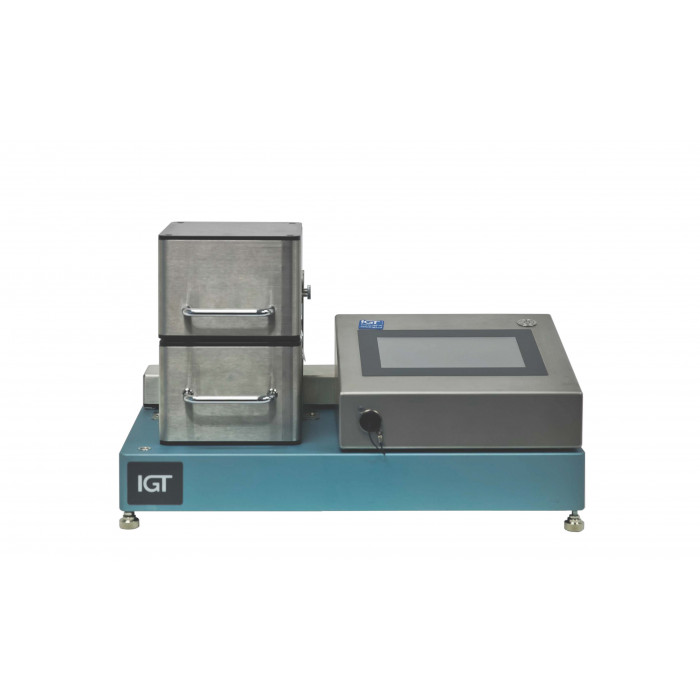

SizeOscope

The IGT SizeOscope is an automated device to determine the sizing of paper and board through the change in reflectivity. It is especially designed to be used with watery liquids of all kinds, its materials coming in contact with the liquid are suitable for all usual liquids common in the paper industry.

The whiteness decreases because of the show-through of the penetrating ink. The measurement starts when a high contrast liquid contacts the paper, the measured reflection starts at 100 % and the penetration is visible as a reduction of the reflection. Factors influencing the reflection are brightness, color and opacity of the paper. The penetration of the liquid is influenced by the sizing agent, sizing level, and hence the hydroscopy of the paper, as well as on the type of liquid used. The measurement can be stopped automatically after reaching a pre-set drop of reflection, after a pre-set time, or manually.

The test liquid is contained in a closed container, it is pumped to the sample and flows over the edge of the contact area, this guarantees a continues fresh flow of liquid, without pressure on the substrate. One liquid filling lasts for at least 100 tests on 80 g/m² paper.

The measurement area is illuminated by a uniform LED light source. The camera in the IGT SizeOscope measures the reflection of the visible image, a graph of reflection in time and the actual image are presented and the computer records the measurements and stores the images. All data can be exported for external analysis.

Wood fibers and cellulose fibers are hydroscopic, so paper made of these fibers can easily be wetted. In many cases the paper has to be more water repellant to make it writable or printable. To reach this, the papermaker adds a sizing agent, rosin, AKD or ASA, to the paper stock. A low amount reduces the Cobb value and makes the paper writable, more makes the paper water repellant and hard sized (low Cobb value). The sizing can be determined in different ways; commonly by determination of the water absorption with a colored water with or without other additives to enhance the effect. The Cobb value gives no information on the speed of absorption.

Surface sizing is something completely different. For surface sizing starch is applied on the surface of the paper in the size press at the end of the paper machine before the last dryer section and the calan- der. Surface sizing is needed to improve the surface strength of the paper. Paper can be (stock or mass) sized and surface sized.

Liquids:

There are different inks or colored liquids available for sizing tests. In general, it is important to get sufficient color discrimination between the penetrating liquid and the paper

• Blue ink in conformance with DIN 53126

• Black ink in conformance with DIN 53126

• All inks as specified in TAPPI T530 can be used.

• Other liquids can be used as long as the pump mechanism is not affected.

Options:

Pinhole detection: It is possible to record individual spots of ink passing through the paper, pinholes, before the overall level of penetration has reached the threshold value.

Temperature control: A version with temperature controlled liquid container is available.

Video-recording: An option is available for video image storage with different frame rates.

Exchangeable liquid containers for quick change of liquids.

| Weight: | 15kg |

| Dimensions(L x W x H): | 30cm x 45cm x 30cm |

| Model: | 572.000.100 |

| Standard delivery time: | 6-8 weeks |